Top 10 Qualities in a Sterile Manufacturing Equipment Manufacturer

Looking for a reliable sterile plant manufacturer? Discover 10 must-have traits every pharma sterile equipment supplier should offer. Read before you decide.

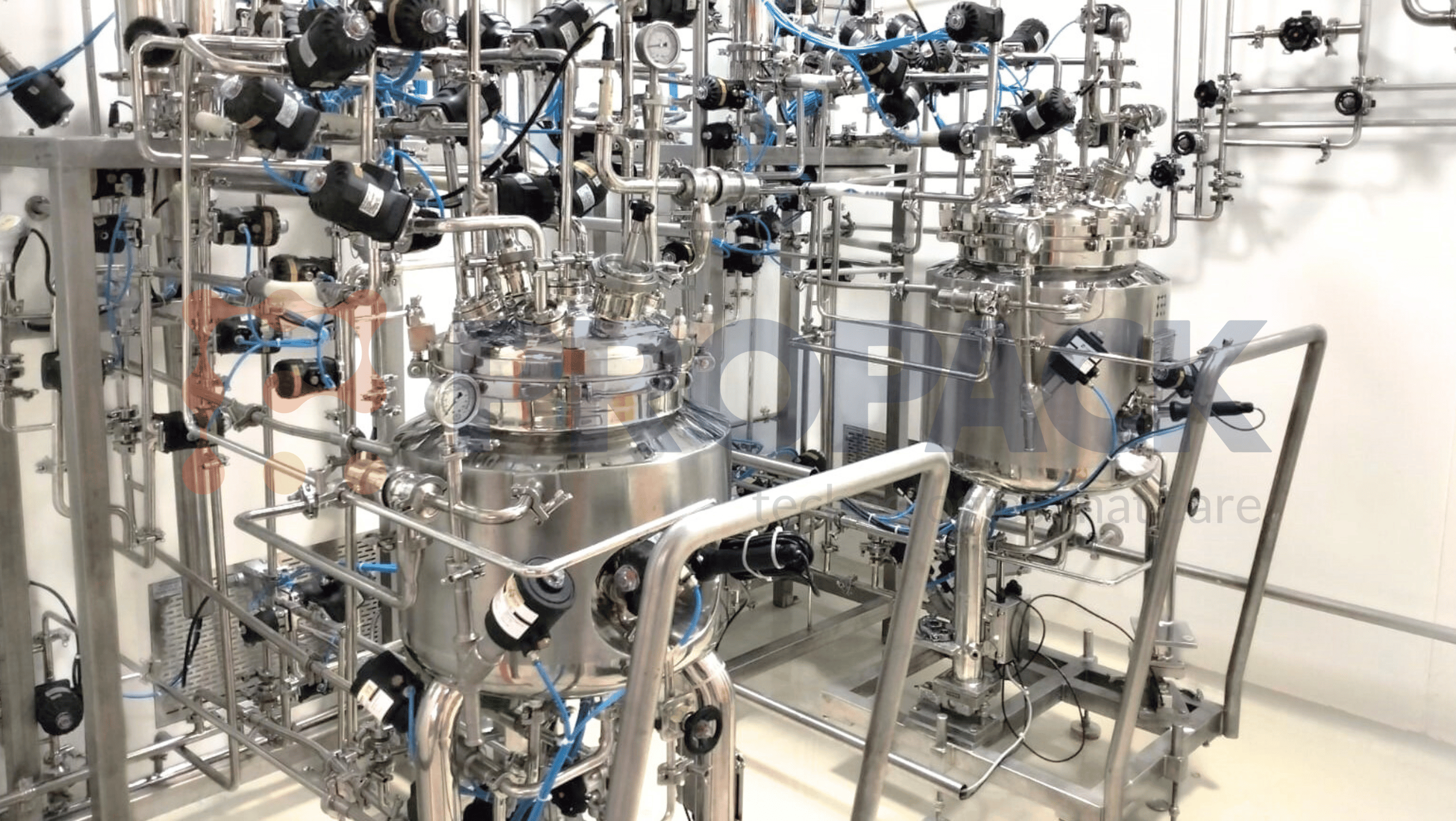

Read MoreHow Smart Design Cuts Cleaning Time by 40% in Sterile Plants

Learn how smart design choices in sterile plant equipment can reduce cleaning time by up to 40%, leading to improved productivity and compliance.

Read MoreSterile Drainability: The Overlooked Factor That Can Lead to Microbial Breeding Grounds

Improper drainability in sterile manufacturing equipment can lead to microbial contamination. Learn how vessel design impacts sterility and compliance.

Read MoreKey Factors to Consider When Selecting a Pharmaceutical Machinery Manufacturer

Selecting a reliable pharmaceutical machinery manufacturer is a critical decision that affects the overall efficiency, quality, and compliance of production processes. With numerous options available, it is essential to identify the key factors that ensure a successful partnership.

Read MoreThe Competitive Edge of Partnering with Pharmaceutical Machinery Manufacturers in India

The global pharmaceutical industry is fiercely competitive, with manufacturers seeking every possible advantage to stay ahead. One significant strategic advantage lies in partnering with Indian pharmaceutical machinery manufacturers.

Read MoreONE MIXER, ENDLESS POSSIBILITIES! Applications of multimixers in cosmetic manufacturing

In the dynamic world of cosmetic manufacturing, precision and efficiency are paramount. Propack Technologies proudly introduces its Multimixer Solutions, a sophisticated blend of technology and innovative design. Read MoreHow to Maintain Uniform Particle Size in Ointment Production?

Achieving consistent particle size in ointment manufacturing is essential for producing high-quality semi-solid products. Variations in particle size can affect the texture, stability, and efficacy of the final product.

Read MoreIs Foaming impacting your processing efficiency?

Foaming is a common issue that can affect the quality and efficiency of cosmetic manufacturing processes. Foaming can be caused by various factors, such as the presence of surface-active agents, the mixing conditions, and the addition of solids and powders.

Read MoreAre Vacuum Transfer Systems the missing piece in your manufacturing puzzle?

Vacuum transfer systems are a great solution for transferring liquid and semi-solid materials in your pharmaceutical, biopharmaceutical or cosmetic manufacturing plants. They can offer you speed, efficiency, safety, hygiene, quality and accuracy, as well as flexibility and customization, to suit your specific needs and requirements.

Read MoreContra or Semi Contra Agitator: Which is the Superior Choice?

In the machinery manufacturing industry, the choice of equipment can significantly impact the efficiency and quality of operations. One such critical decision is the selection between a Contra Agitator and a Semi Contra Agitator. This blog aims to provide an in-depth comparison of these two types of agitators, helping you make an informed decision.

Read MoreHow to Choose the Best Sterile Liquid Plant Manufacturer for Your Pharma Business

Sterile liquid manufacturing is a crucial process in the pharmaceutical industry, as it involves the production of various types of sterile solutions such as vials, IV fluids, aerosols, ampoules, and LVP - SVP solutions.

Read More

From Vaccines to Cell Therapy: The Amazing Products of Sterile Manufacturing Plants

A Sterile Manufacturing Plant is a facility that produces pharmaceutical products that are free from any viable microorganisms or endotoxins. These products are usually administered into the body through injections, infusions, inhalations, or implants.

Read More

An over view of Ointment manufacturing plant

Ointment cream manufacturing plants are specialized machines that produce ointments, creams, lotions, gels, and other semi-solid products for the pharmaceutical, cosmetic, and biotech industries.

Read More

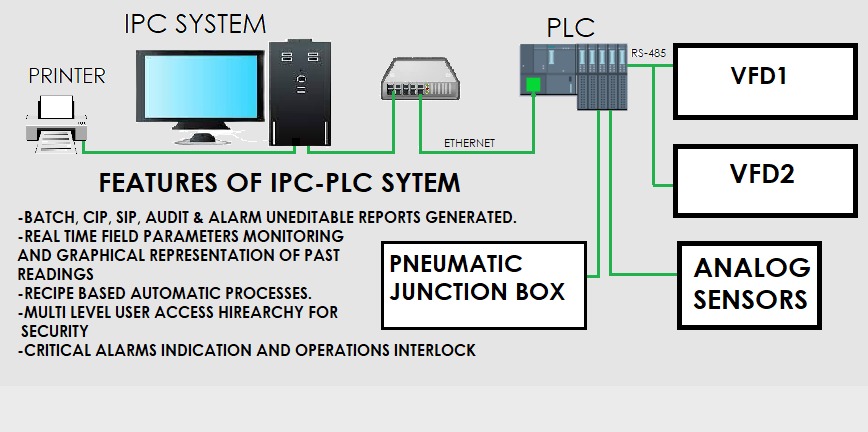

SCADA and Automation

The need of Automation and Monitoring systems is increasing day by day. The use of automated systems reduces human intervention thereby giving a lot of advantages such as increased efficiency, no human touch and error. All of PROPACK’S equipment are available in automated options as well.

Read More

Remote Installation with only online support

In any kind of industry, especially pharmaceutical industry the documentation and drawings of manufacturers play an important role. These kind of documentations help the end user, the manufacturer, maintenance and the production team help in quick and easy installation and servicing of the plant.

Read More

Vessel Design Enhancement to increase the throughput

Faster batch processing with consistent and optimal quality is a common goal for Pharmaceutical Industries. It’s often the impetus for adding more processing equipment. But improving throughput can involve much more than simply adding capacity. When you add a new processing vessel to your line, move up to a larger capacity or replace an existing unit, you have the unique opportunity to consider design options that can optimize your overall performance.

Read More

.png)