The Importance of Toothpaste Manufacturing Plant in the Industry Today

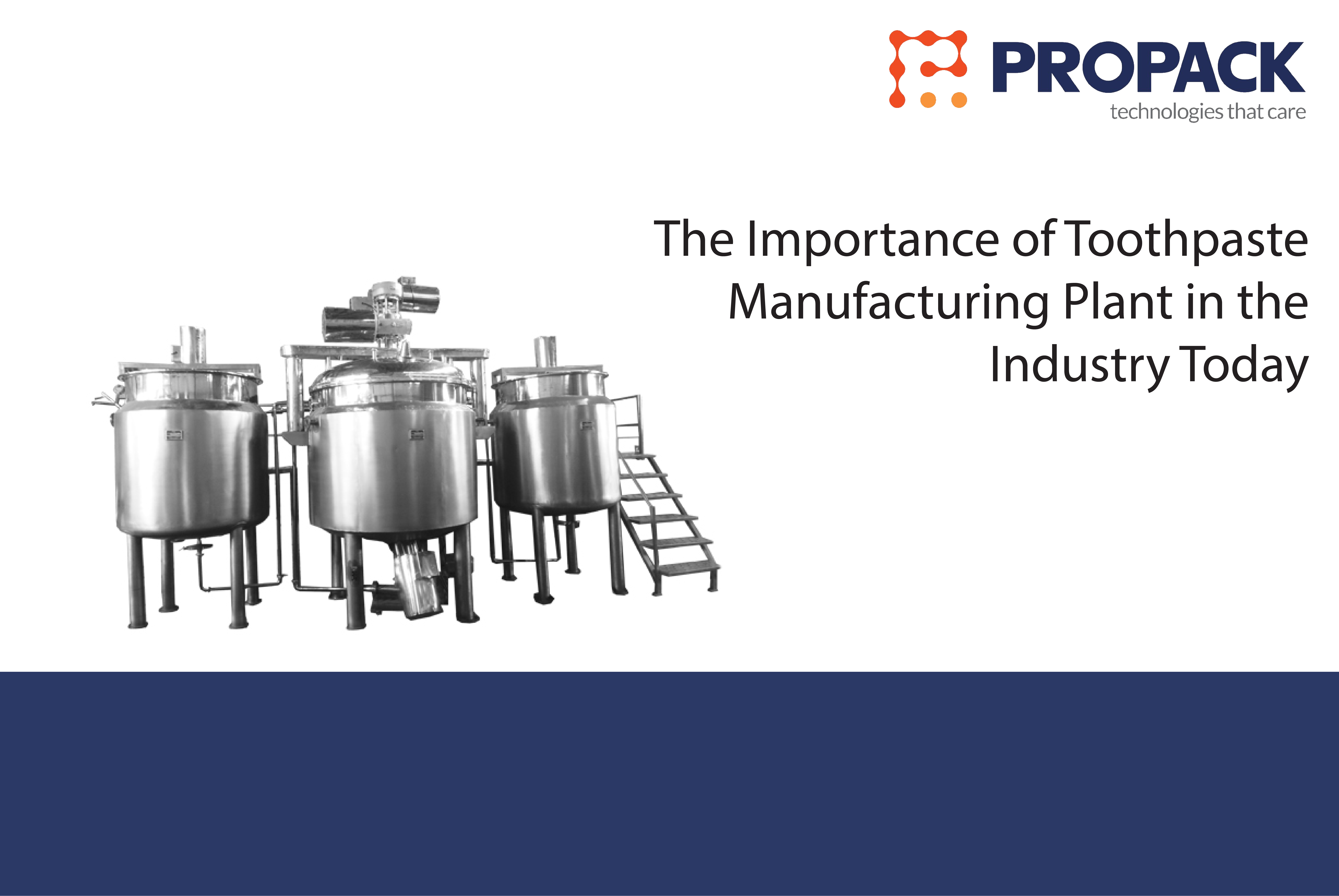

A toothpaste manufacturing plant is a manufacturing vessel used for various product for mixing blending cosmetics, creams, toothpaste and other viscous products. It consists of a contra design Anchor with detachable PTFE scrappers with clockwise anti-clockwise resolution of agitator. Also, the plant is provided with paddle-type blades that is used for moving the substance in the middle of the container. The paddle type blades are centrally installed and are connected with a hollow shaft.

The mixer is designed to be robust such that it works efficiently in an elevated vacuum condition without hampering the structure or process. Scalability comes into the picture when the number of ingredients used for the formulation of the cream in the cosmetic manufacturing plant is very high. There has to be a formulated method which means that the process to create 600 liters of cream must be scalable to create 100 liters or 1200 liters of cream. Scalability defines a base for the entire toothpaste manufacturing process and it does not matter whether the quantity of production is huge or small.

The mixer is designed to be robust such that it works efficiently in an elevated vacuum condition without hampering the structure or process. Scalability comes into the picture when the number of ingredients used for the formulation of the cream in the cosmetic manufacturing plant is very high. There has to be a formulated method which means that the process to create 600 liters of cream must be scalable to create 100 liters or 1200 liters of cream. Scalability defines a base for the entire toothpaste manufacturing process and it does not matter whether the quantity of production is huge or small.

One of the important reasons for the use of toothpaste is hygiene. In our day-to-day lives, we have to keep our bodies healthy by maintaining hygiene. Oral hygiene is also one of the important classes of hygiene and toothpaste plays a major role in keeping your oral health good.

Let us discuss some of the advantages of using Toothpaste Manufacturing Plants.

Toothpaste is one of the most widely used products in the market today. People from all over the world use toothpaste daily and that is why toothpaste is in high demand. By using a toothpaste manufacturing vessel, the toothpaste manufacturing organization can produce toothpaste at a much faster rate which is generally not possible with manual or primitive manufacturing methods.

With toothpaste manufacturing plants, the material required for the production of toothpaste is very less. This feature reduces the overall cost of toothpaste generation and increases profitability.

Power consumption is one of the most important factors in any industry. If a machine consumes large power, then it can increase the overhead cost of the production process. The modern toothpaste manufacturing plants are designed to consume less power and eventually increase profitability.

A Modern toothpaste manufacturing plant comes with hygiene and safety standards. The toothpaste developed from a toothpaste manufacturing vessel is perfectly good for hygiene as there is no direct involvement of any human during the production process. The entire production process is automated and only a limited amount of people are required to monitor and control the entire process. As the number of people required is very less, the safety associated with the manufacturing process also increases.

There are also other special features of using toothpaste manufacturing plants. The material used for the structure of toothpaste manufacturing plants is generally made up of stainless steel. The blender and powder mixing equipment used in toothpaste manufacturing vessel is also made up of stainless steel. The floor space required for the instalment of the toothpaste manufacturing vessel is also very less. The plant is provided with a hydraulic lifting arrangement for the maintenance and conversion of products. Also, a temperature indicator is automated and installed in the toothpaste manufacturing vessel to indicate the temperature of the cream when it is processed in the manufacturing plant.

There are various advantages of using toothpaste. Toothpaste consist of abrasive products that are gentle on the teeth, but at the same time strong enough to remove the plaque from the teeth. The toothpaste contains antimicrobial ingredients to minimize the risk of infected gums. Nowadays, toothpaste serves multiple purposes and for this reason, the chemical composition of the toothpaste is very complex. An ideal toothpaste should have properties such as abrasion, froth, sweetening, bleaching, prevention of microbial growth and decay and that is why it is very essential to use a Toothpaste manufacturing plant for the production of toothpaste that complies with the modern toothpaste quality standards.