Cough Syrup Manufacturing Plant

Propack Technologies’ Liquid processing systems for batch sizes ranging from 10 L to 30,000 L are suitable to manufacture liquid solutions like orals, liquids, suspensions, cough syrups, drop solutions, expectorants, antacid solutions and other similar products. We offer completely customized systems adhering to cGMP and ASME BPE guidelines in case of aseptic manufacturing.

We offer a full range of process vessels and their automation - comprising optional SCADA package - as well as all associated peripherals including suction pumps, CIP/SIP systems, and the filling line interface with transfer pump.

Benefits

- 1Vacuum transfer for sugar

- 2Long bend pipelines to reduce residue in pipelines

- 3Liquid glucose transfer system

- 4Efficient mixing with bottom entry agitator

- 5Inline High Shear mixer for suspension

- 6In-house programming expertise to design customized recipe cycles

- 7Automation as per 21 CFR Part 11, PLC / SCADA based automation

We offer the following customizations according to client specific needs,

- Main manufacturing vessel

- Sugar melting vessel

- Premix vessel

- Sugar discharge bin

- Basket filter

- Zero holdup filter press

- Storage vessel

- Vacuum pump

- Transfer pump

- Metering pump for Filling station integration

- Control panel

- Interconnecting pipeline

- Working platform

- CIP and SIP modules

- Automated product transfer

- Automatic Temperature Control with PID

- Load Cells

- SCADA system architecture

A standard liquid solution like syrup manufacturing takes place in three different phase vessels – A premix vessel, a sugar melting vessel and a main mixing vessel. Other components may include sugar charging bin, basket filter, a zero holdup filter press, an inline homogenizer, a vacuum pump, transfer pump, storage and buffer vessels and a CIP module. All our vessels are made of SS316L grade material and fabricated as per cGMP guidelines. The plant can be completely automated with pneumatically operated valves for aseptic manufacturing.

Sugar Melting vessel

Melting of sugar and other similar substances is carried out in the sugar melting vessel. The vessel is jacketed for heating and cooling of the solution in the vessel. The temperature variation of the vessel could be achieved by steam & chilled water or electrical heating arrangement according to the availability of utilities at the customer’s facility. For uniform mixing, a propeller type stirrer is utilized along with baffles to prevent vortex formation. Product inlet into the vessel can be achieved via vacuum suction for minimum contamination. Similarly, solid ingredients can also be introduced into the solution at vacuum pressure. Solid ingredients can be introduced into the vessel from the sugar discharging bin via an additive hopper at the top of the vessel or a suction port situated at the bottom of the vessel. After obtaining the satisfied composition the contents of the vessel are transferred to the main manufacturing vessel via the basket filter to remove any impurities present in the sugar solution.

Premix vessel

The premix vessel is used in mixing the ingredients before addition of glucose or sugar. This pre-mixing process increases the efficiency of mixing. The vessel is usually jacketed to improve solubility at elevated temperatures. The temperature variation of the vessel could be achieved by steam & chilled water or electrical heating arrangement according to the availability of utilities at the customer’s facility. For uniform mixing, a propeller type stirrer is utilized in this vessel. Product inlet into the vessel can be achieved via vacuum suction for minimum contamination. Similarly, solid ingredients can also be introduced into the solution at vacuum pressure. After obtaining the satisfied composition the contents of the vessel are transferred to the main manufacturing vessel.

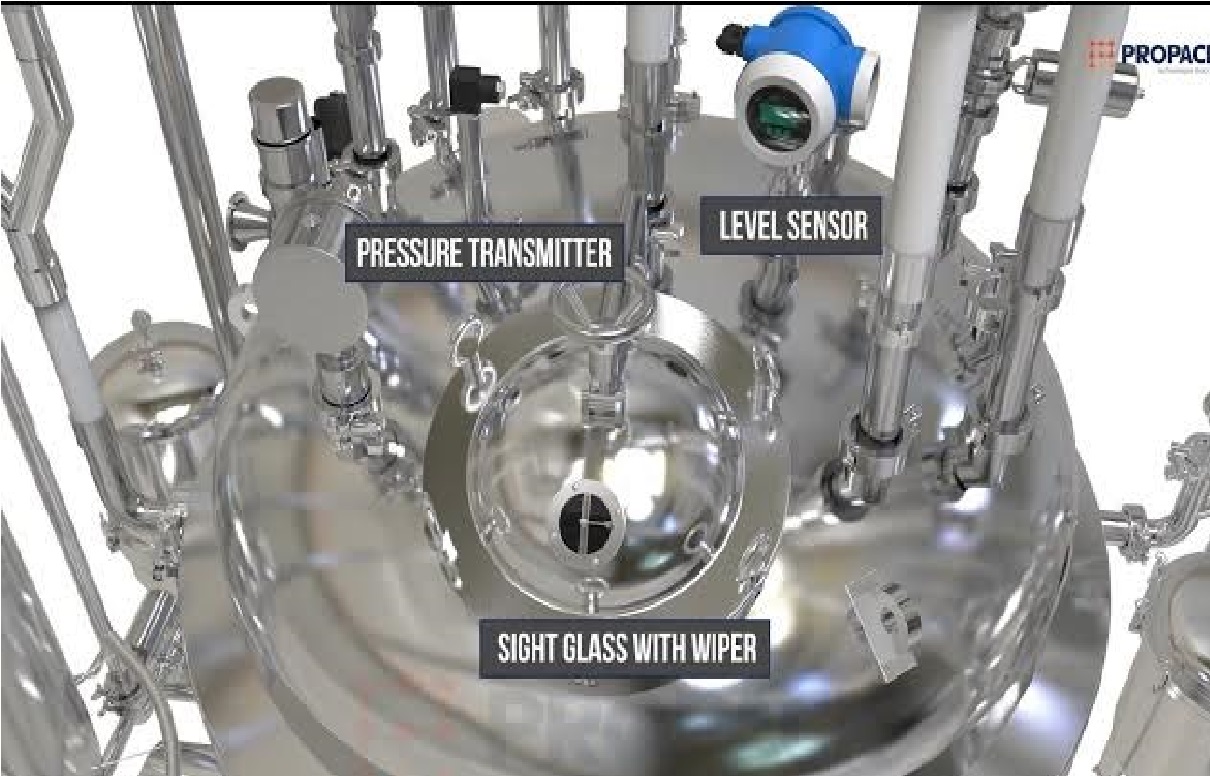

Main Manufacturing vessel

The main mixing of the contents in the sugar melting vessel and the premix vessel is done in the main manufacturing vessel at appropriate temperature. The temperature variation of the vessel could be achieved by steam & chilled water or electrical heating arrangement according to the availability of utilities at the customer’s facility. Usually, the main mixing vessel is provided with a bottom mounted propeller type stirrer to stir the product for uniform temperature transfer and minimizing lump formation. Apart from the agitator, an inline homogenizer is provided for grinding the mixture to a uniform composition. Propack technologies’ homogenizer is designed to reduce particle size to less than 5 microns. After attaining the desired composition and viscosity of the product, the contents are transferred into a storage vessel through a flush bottom diaphragm valve to minimize product holdup in the tank. The contents are filtered via a zero-holdup basket filter before dispatching into the filling line

The operations of various pumps, pneumatically operated valves (in case of automated operation) and stirrers is carried out through the main control panel. The panel is made out of SS304 grade material and consists of various safety lock systems like the Emergency stop and Mains supply indicators for safe work and extended component life. The vessels are connected to each other via interconnecting pipelines manufactured as per cGMP norms and connected with sealed tri clamp connection.

Features of our system:

- Uniform ingredient dispersion

- No wall caking

- Entire plant operation by one operator and one helper

- Efficient heat transfer in the vessels

- Particle size reduction less than 5 microns

- Reduced batch processing time

- Reduced change over time

- Consistent product composition across different batches

- All contact parts made of SS316L and non-contact parts made of SS304 grade material

- Food grade silicone gaskets

- Vessel design as per ASME guidelines

- Torispherical, Hemispherical and Conical dish top customization availability

- Hydraulic lid lifting arrangement for occasional cleaning

- Static & Dynamic spray ball availability

- VFD for motor rpm controls

- Double cartridge mechanical seal along with cooling arrangement for Homogenizer shaft