Ampoules Manufacturing Plant

Propack Technologies: A leading provider of Ampoule Manufacturing Equipment for sterile solutions. Our machines can handle capSacities ranging from 5 L to 30,000 L, producing high-quality products such as vials, IV fluids, aerosols, ampoule, and LVP - SVP solutions. We customize our systems to meet the cGAMP and ASME BPE standards for aseptic manufacturing.

Our ampoule processing systems encompass a full range of process vessels and their automation, with an optional SCADA package for enhanced control and monitoring. Additionally, we supply all the necessary peripherals, including suction pumps, CIP/SIP systems, and the filling line interface with transfer pump.

Benefits of Ampoules Manufacturing Plant

- 1Aseptic mixing & blending vessels designed as per ASME BPE / cGAMP / PED / USFDA

- 2Bottom mounted magnetic mixer as per requirements

- 3Skid customized & engineered as per process requirement

- 4Complete CIP / SIP able system with 100% drain

- 5In-house programming expertise to design customized recipe cycles

- 6Automation as per 21 CFR part 11

- 7Aseptic Block Valves are used to minimize dead zones

We offer the following customizations according to client specific needs:

- Manufacturing vessel

- Holding Vessel

- Magnetic Mixers

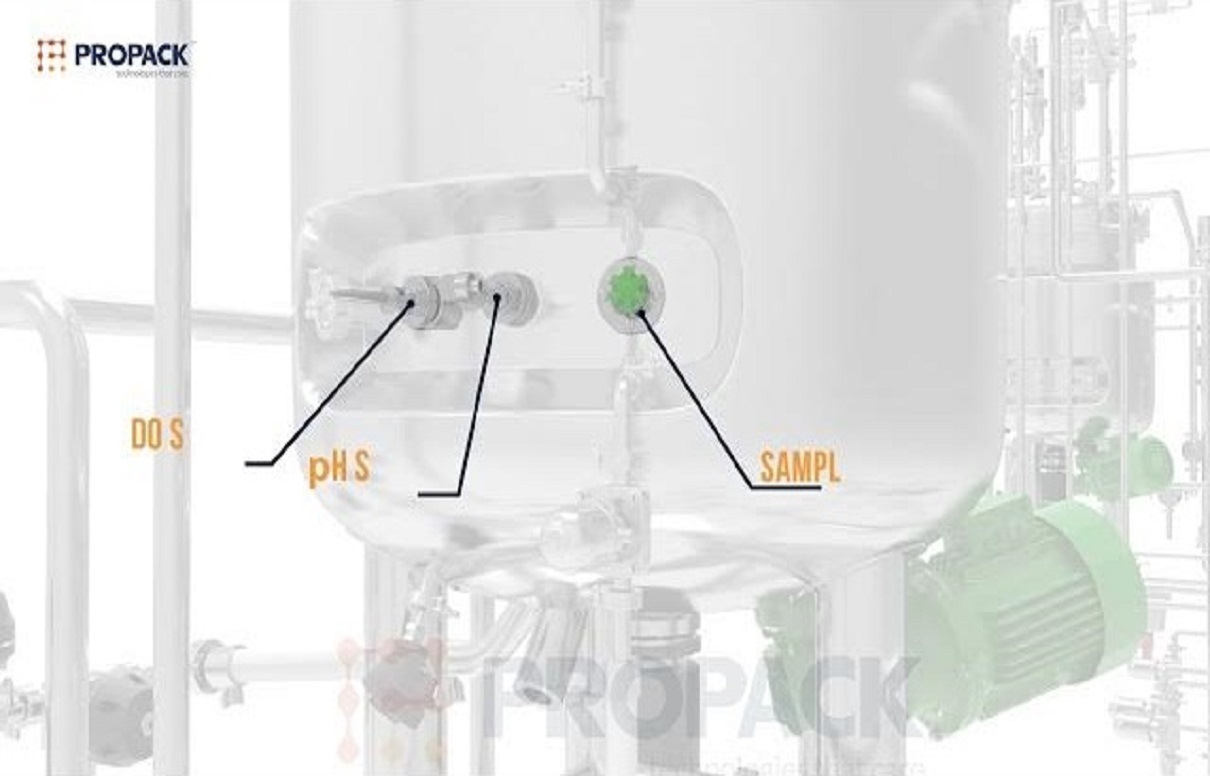

- Sampling Valve

- Conductivity Sensor

- DO sensor

- pH Sensor

- Product Filter

- CIP - SIP of entire skid

A standard sterile aseptic manufacturing system comprises two vessels, although the systems might vary considerably according to individual needs. Complete isolation from contamination remains the primary consideration in Ampoule Manufacturing Plants. Each vessel is therefore designed in accordance with cGAMP and ASME BPE guidelines. The vessels can be customized to include magnetic mixers based on product requirements. Additionally, various sensors such as pH sensors, DO sensors, Conductivity sensors, Level sensors, and charting devices can be integrated into the automatic ampoule manufacturing machine as needed.

The operations of centrifugal pumps, pneumatically operated valves (in the case of automated operation), and mixers are carried out through the main control panel. This panel, constructed from SS304 grade material, features various safety lock systems, including Emergency Stop and Mains Supply Indicators, ensuring safe work practices and extended component life. The vessels are interconnected via pipelines manufactured in accordance with cGMP norms and connected using sealed tri-clamp connections. These pipelines are meticulously designed to maintain sterility and integrity throughout the manufacturing process, facilitating efficient transfer of materials between vessels while minimizing the risk of contamination. Additionally, the use of sealed tri-clamp connections ensures a secure and reliable connection, further enhancing the overall safety and reliability of the manufacturing system.

Features of Our Sterile Processing Equipment :

- Uniform ingredient dispersion

- No wall caking

- Entire plant operation by one operator and one helper

- Efficient heat transfer in the vessels

- Particle size reduction less than 5 microns

- Reduced batch processing time

- Reduced change over time

- Consistent product composition across different batches

- All contact parts made of SS316L and non-contact parts made of SS304 grade material

- Food grade silicone gaskets

- Vessel design as per ASME guidelines

- Torispherical, Hemispherical and Conical dish top customization availability

- Hydraulic lid lifting arrangement for occasional cleaning

- Static & Dynamic spray ball availability

- VFD for motor rpm controls